Using winding technology for universal motors, E.GO can provide the following functions during product production:

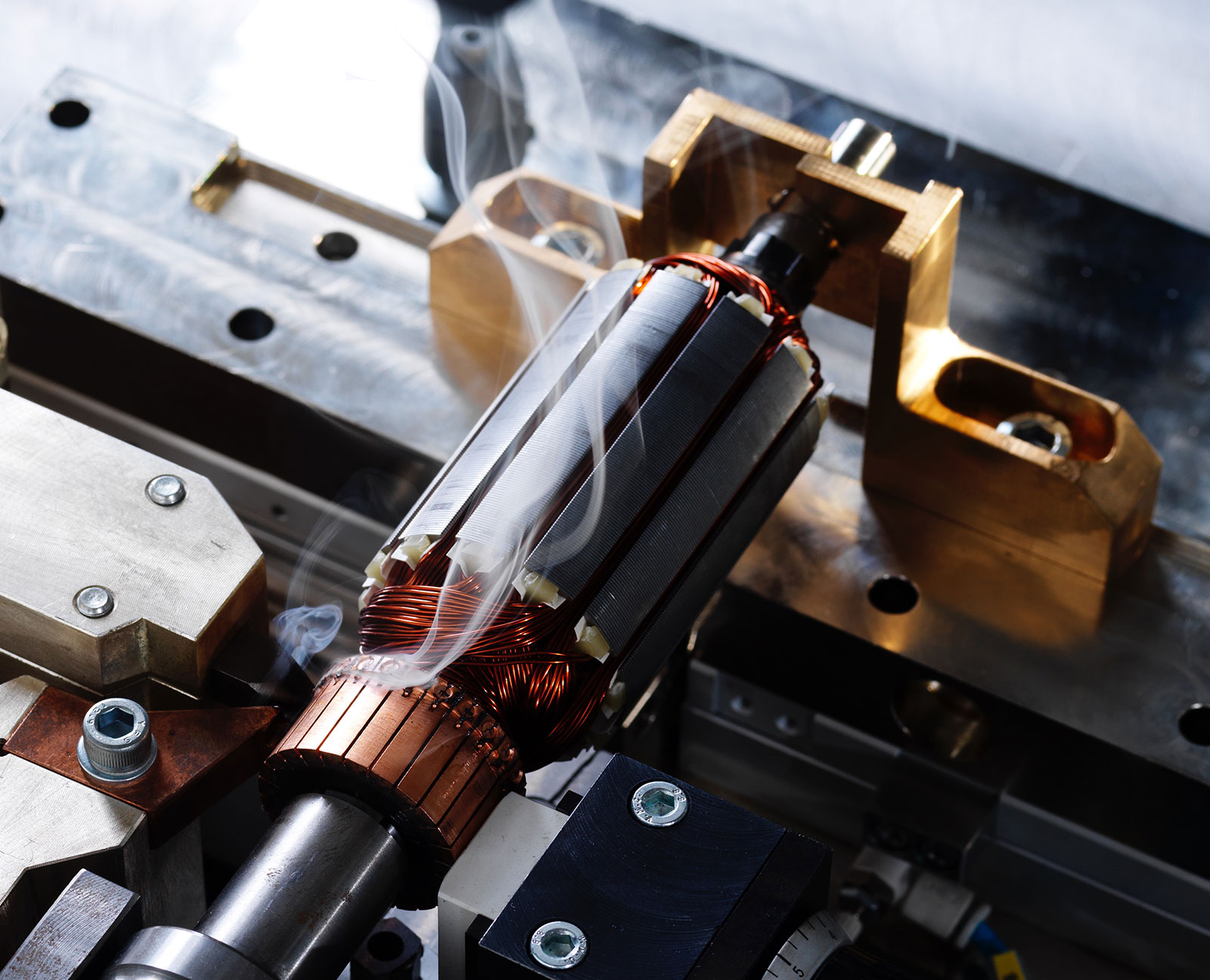

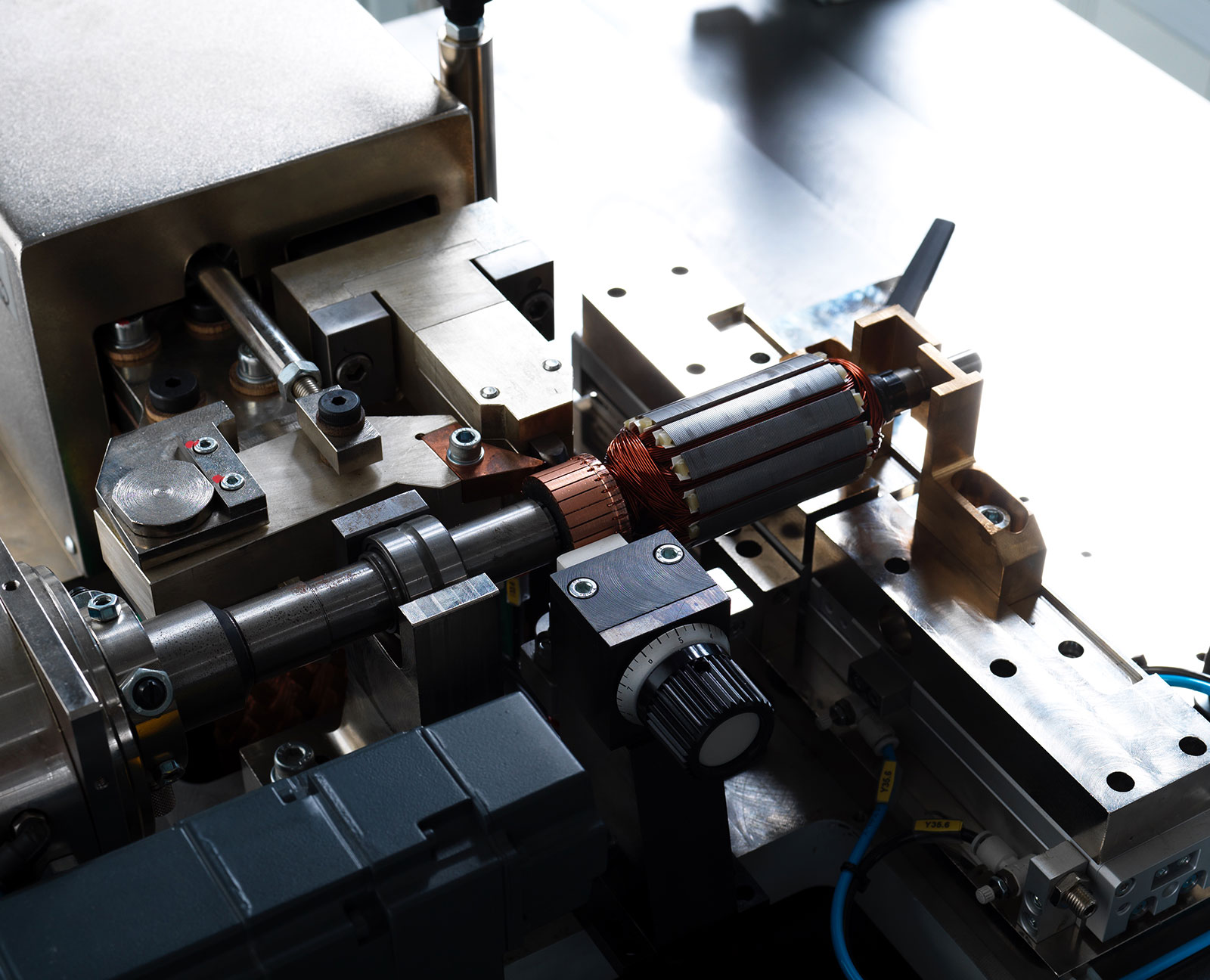

- Rotor winding: programmable wire stratification with flyer winding technology for high slot fill and accurate coil wire positioning.

- High-speed flyer winding of rotors to reach maximum productivity.

- Winding of universal stators with programmable wire stratification with needle winding technology for high slot fill and accurate coil wire positioning.

- Winding of universal stators with high-speed needle winding technology.

- Fully programmable wire termination system using robotics to carry out complex coil interpolations and wire-lead cuts in short time and limited space.

- High speed, precision insulator paper formation and placement.

- Multi-station high-speed machines to increase productivity and reduce operating space.

- Quick tooling change system to optimize and speed up production changeover times.

- E.GO machines are equipped with a monitoring software that instantaneously supplies a vast amount of information useful for performance analysis and diagnostics, such as production data, yields and alarms. The software allows storing the data and the alarm log history and provides traceability for each single piece.